Fiber Mixed Mortar Composite Insulation Board & Pipe

Glass wool panels are an ideal insulation material for global markets due to their fire resistance, durability, and energy efficiency. They provide cost-effective insulation solutions while meeting international safety and environmental standards. Their lightweight nature also reduces transportation costs, making them a highly demanded product in the nsulation industry.

Technical Specifications

| Property | Unit | Performance | Test Standard |

|---|---|---|---|

| Density | Kg/m³ | ≤95 | GB/T6343 |

| Flame Retardancy | – | ≥ B2 | GB/T8624 |

| Thermal Conductivity (0°C) | W/(m·K) | ≤0.034 | GB8624-2006 |

| Thermal Conductivity (40°C) | W/(m·K) | ≤0.036 | GB/T10294 |

| Water Vapor Permeability Resistance | – | ≥7.0×10³ | – |

| Water Absorption Rate | % | ≤10 | GB/T17794 |

- Lightweight & durable – Low density (≤ 95 Kg/m³)

- Superior thermal insulation – Low thermal conductivity (≤ 0.034 W/m·K)

- Excellent water & vapor resistance – Moisture-proof structure

- Eco-friendly & safe – Non-flammable, non-toxic

- Wide temperature range – (-40°C to 110°C)

- Long-lasting performance – Resistant to bending and cracking

This high-performance insulation system is ideal for industrial pipelines, cold storage facilities, ventilation systems, and energy-efficient building projects.

Below, the international quality standards table highlights the superior performance of this product in thermal insulation, water resistance, and durability.

International Quality Standards Table

| Test Item | Unit | Performance Requirement | Test Method / Standard |

|---|---|---|---|

| Density | Kg/m³ | ≤ 95 | GB/T6343 |

| Thermal Conductivity | W/(m·K) | ≤ 0.034 (at 40°C) | GB/T10294 |

| Vapor Permeability | G/(m·s·pa) | ≤ 2.8×10⁻¹³ | GB/T17146-1997 |

| Water Absorption | % | ≤ 10 | GB/T17794-2008 |

| Impact Resistance | N/cm | ≥ 2.5 | GB/T10808 |

| Temperature Resistance | °C | -40°C to 110°C | GB/T17794 |

| Fire Resistance | – | Non-flammable, non-toxic | GB/T16259 |

This product is an excellent choice for international customers looking for high-performance, energy-efficient, and eco-friendly insulation solutions.

Application Method

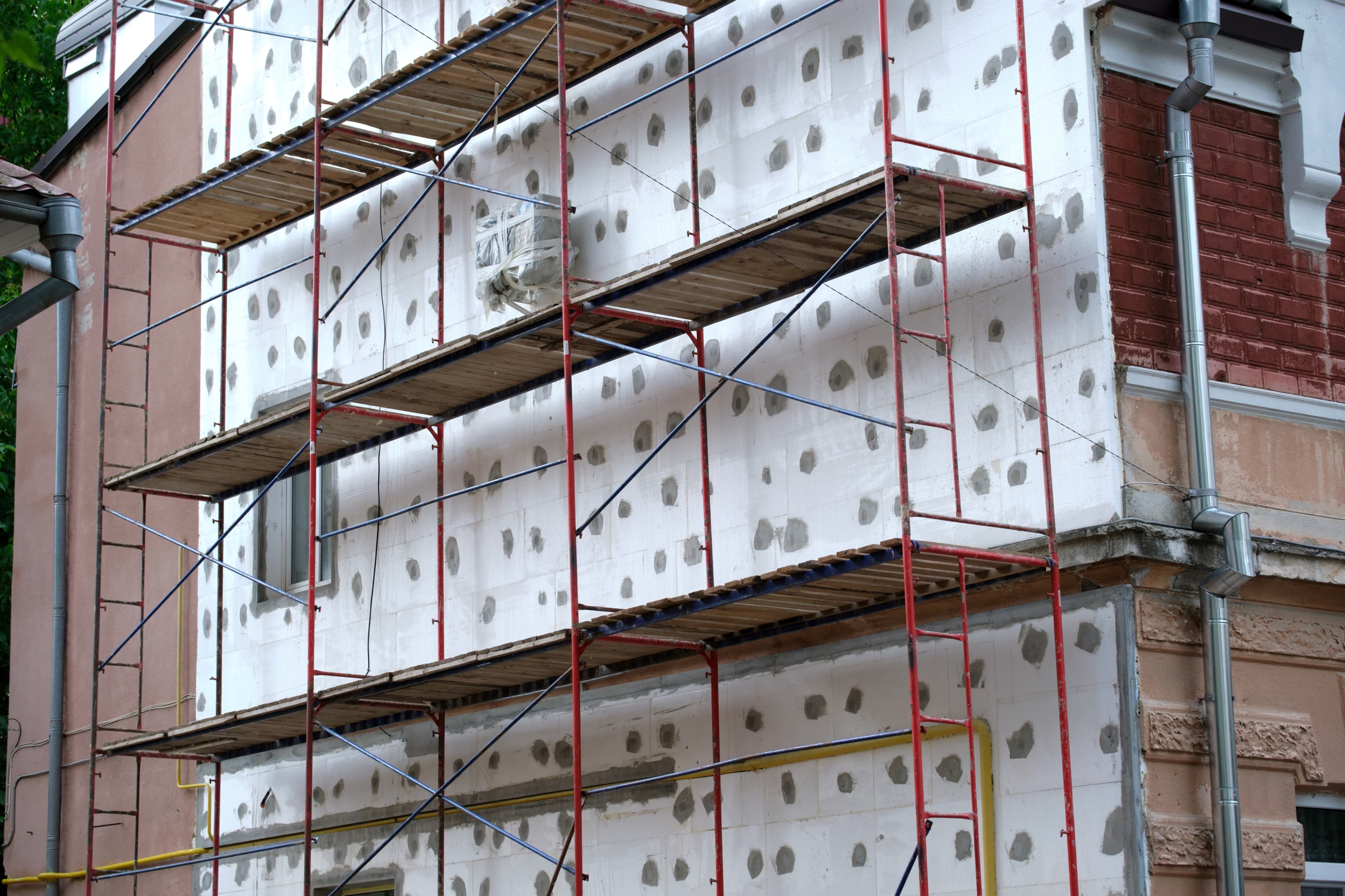

Fiber Mixed Mortar Composite Insulation Board & Pipe can be applied to various surfaces that require insulation. It is widely used in HVAC systems, pipelines, cold storage facilities, and building insulation.

Step-by-Step Application

- Surface Preparation

- The surface must be clean, dry, and smooth before installation.

- Remove any dirt, oil, or loose materials.

- Cutting and Shaping

- The material is cut and shaped according to the required dimensions.

- For pipe insulation, pieces should be cut according to the pipe diameter.

- Installation & Fixing

- The insulation board or pipe covering is placed firmly on the surface.

- It is secured using adhesive or mechanical fasteners (clips, nails, etc.).

- For pipes, joints should be sealed using special tape or hot welding techniques.

- Sealing Joints

- All joints must be sealed with special insulation tape to prevent heat leakage.

- If used outdoors, a waterproof protective coating should be applied.

- Final Inspection & Maintenance

- After installation, check for any gaps or loose areas.

- Regular maintenance ensures long-term insulation performance.

- After installation, check for any gaps or loose areas.

Quality

Rubber insulation pipes play a crucial role in moisture control and have widespread applications in daily life. However, proper installation and usage are essential to avoid potential issues. Fire-resistant rubber insulation pipes enhance fire safety but can cause problems if not applied correctly. Below are key considerations during installation:

- Installation of Fire-Resistant Rubber Insulation Pipes

- If insufficient adhesive is applied at connection points, the insulation may loosen over time.

- Paint Application

- If the exterior surface of the rubber insulation pipe is not coated with protective paint, it may be vulnerable to external damage.

- Before applying paint, the pipe surface should be cleaned of dust and debris.

- Installation During Summer

- Avoid overstretching the rubber insulation material, as excessive stretching can damage the surface, especially in colored rubber pipes.

- Installation in Low Temperatures

- It is not recommended to install rubber insulation pipes when the outdoor temperature is below 5°C.

- At low temperatures, adhesives lose their effectiveness, reducing overall product performance.

Rubber Insulation Pipes – Information Guide

The closed-cell foam structure has a low thermal conductivity, providing excellent thermal insulation and reducing energy consumption. Its closed-cell structure and dense outer surface prevent water vapor penetration and ensure a low water absorption rate. The product is highly flexible, extremely easy and safe to install, saving both labor and material costs. The exterior is elegant and clean. It has excellent weather resistance within a wide temperature range (-40°C to 120°C) and is durable for long-term use.

With a unique fire-retardant formulation, the material is flame-resistant. The closed-cell foam structure effectively insulates against water vapor, meaning that even if the product surface is damaged, the overall insulation performance remains unaffected, eliminating the need for an additional vapor barrier layer.

Its superior resistance to water vapor penetration, low water absorption rate, and low thermal conductivity ensure long-term stable insulation performance. Compared to other insulation materials, it can be used in thinner layers, reducing labor costs. It has an outstanding fire-retardant effect, is self-extinguishing, non-flammable, and meets fire safety requirements.

With a wide range of applications, the material is resistant to various weather conditions and has excellent aging resistance. It is highly durable against extreme cold, heat, dryness, and humidity over the long term. Its high flexibility makes installation easy, while the clean and aesthetically pleasing exterior enhances its appearance. Additionally, it provides sound insulation and vibration reduction effects.

Below is a table showcasing product specifications based on different pipe diameters and thicknesses:

| Copper Pipe Outer Diameter (Inch) | Seamless Pipe Outer Diameter (mm) | Nominal Diameter (DN) | Rubber Inner Diameter (mm) | 9mm Thickness (1.8m/pc) | 15mm Thickness (2m/pc) | 20mm Thickness (2m/pc) | 25mm Thickness (2m/pc) | 30mm Thickness (2m/pc) |

|---|---|---|---|---|---|---|---|---|

| 1/4 | 6 | 6 | 6×9 | 180 | – | – | – | – |

| 3/8 | 10 | 6 | 10×9 | 140 | 10×15 | 80 | 10×20 | 70 |

| 1/2 | 13 | 8 | 13×9 | 120 | 13×15 | 100 | 13×20 | 50 |

| 5/8 | 16 | 8 | 16×9 | 100 | 16×13 | 60 | 16×20 | 50 |

| 3/4 | 19 | – | 19×9 | 100 | 19×15 | 60 | 19×20 | 40 |

| 7/8 | 22 | 15 | 22×9 | 100 | 22×15 | 70 | 22×20 | 40 |

| 1 | 25 | – | 25×9 | 80 | 25×15 | 55 | 25×20 | 30 |

| 1 1/8 | 28 | 20 | 28×9 | 60 | 28×15 | 50 | 28×20 | 30 |

| 1 1/4 | 32 | – | 32 | 60 | 45 | – | – | – |

| 1 1/4 | 32 | – | 34×15 | – | 34×20 | 40 | 34×25 | 25 |

| 1 3/8 | 35 | 25 | 60 | 40 | – | – | – | – |

| 1 1/2 | – | – | 50 | 30 | – | – | – | |

| 1 5/8 | 42 | 25 | 50 | 30 | 43×20 | 30 | 43×25 | 20 |

| 1 7/8 | 48 | 40 | 48×15 | 50 | 48×20 | 30 | 48×25 | 20 |

| 2 1/8 | 54 | – | 50 | 25 | 60×20 | 20 | 60×25 | 15 |

| 2 3/8 | 60 | 50 | 60×15 | 60 | 60×20 | 15 | 60×25 | 10 |

| – | 76 | 70 | 76 | 25 | 76×15 | 25 | 76×20 | 15 |

| – | 89 | 80 | 89 | 20 | 89×15 | 15 | 89×25 | 15 |

| – | 108 | 108 | 108 | 20 | 108×15 | 10 | 108×25 | 10 |